Our service portfolio for timber construction planning

We plan and produce constructively

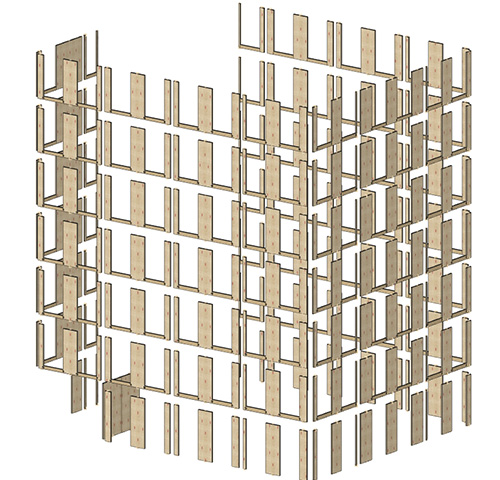

How do we achieve resource-effi cient execution planning for glue laminated timber and CLTPLUS? To ensure projects run smoothly, fi ne-tuning between architecture, structural planning, timber construction and our experienced technical timber construction team is crucial in the early stages of project.

As your industrial partner, we would be happy to assist you while working together to achieve perfect integration of all planning processes. This allows your timber construction project to benefi t from the latest production technologies. The future belongs to timber construction and THEURL's service portfolio really helps projects to achieve success.

SERVICE PACKAGE 2

3D project development with

area optimisation

+ 3D mass determination with areas and waste

optimisation, nesting in advance

+ Classifi cation of components

+ Project is drawn from 2D to 3D

+ Standard composite components

+ Defi nition of the lifting equipment and required

processing

+ Clarifi cation of all special processing, if

available or defi ned in the plan

SERVICE PACKAGE 3

3D project development with

cross-section optimisation

+ All services of package 2

+ Review of optimisation proposals for the static

cross sections (preliminary design), fi nal review

by a structural engineer required

+ Detailed suggestions for static fasteners

according to individual requirementsrnis

04

ORDERING

In orders, production capacities are reserved

based on the existing planning status and the

exact delivery date is set. Our digital customer

portal is available for you to track the project

status at any time. Our TIM application also

enables secure and uniform data exchange

for plans and all documents.

05

JOINERY PLANNING

Based on the four common CAD programs

SEMA, Dietrich`s, cadwork and hsbcad, our

internal technical timber construction team

develops waste-optimised detailed planning

and determines the final nesting. In addition,

the error-free execution plan is crucial for

the production of the individual elements,

i.e. the assembly sequence is defined and

all information for the joinery services

including levers has been created.

06

LOGISTICS PLANNING

Loading space optimisation (LRO) allows

the correct order of the individual components

to be determined virtually and in advance.

Important logistics details are planned, such

as the weight and package size, which type of

truck will be used or the country-specific import

requirements for container loading and customs

clearance are defined.

07

PRODUCTION

The modern, highly automated production facilities

produce resource-saving glued laminated timber

and CLTPLUS for modern timber construction.

CLTPLUS panel dimensions

Thickness 60-360 mm,

length 8-16 m,

Width 2.25-3.5 m

Grid dimensions: 225, 245-295,

310, 330 and 350 cm

Cross section of glue laminated timber

Width 60-280 mm, length 6-18 m

Height 120-1280 mm

09

PREFABRICATION

We create options and continually improve

the refinement of our products. With our

special solutions we can offer factory-assembled

weather protection for the whole construction

period, ribbed ceilings, X-FIX connections, stairs

and key TS3 technology.

10

DELIVERY

To ensure smooth and just-intime delivery

to the construction site, a detailed logistics

concept is drawn up in advance with the

project partners. This includes, for example,

coordinating time slots, access routes and

obtaining permits. This ensures that nothing

stands in the way of a smooth delivery.