Special solutions for CLTPLUS

Energy-efficient, durable, recyclable, highly resilient, CO2-neutral and solid – CLTPLUS is not only a really innovative building material of the future, but can be used almost universally. Rigid and dimensionally stable CLTPLUS ceiling elements are ideal when dealing with large spans and low component heights. The high degree of prefabrication guarantees rapid construction progress that can be planned in detail. In addition to a pleasant room climate, the impressive quality of the visible wood also creates an aesthetically pleasing look, which, thanks to its “warm” appearance, allows room temperature to be reduced thus saving energy. This applies to private homes as well as to multi-storey apartment buildings and commercial buildings, kindergartens and schools. The THEURL Joinery Service means individual solutions can be implemented easily for installation levels or stair recesses, as well as cable and pipe ducts.

Moisture protection for CLTPLUS ceiling elements

Visible ceiling elements in particular require special attention during production, transport and assembly. A specially designed, self-adhesive membrane ensures effective moisture protection on the construction site. The membrane is fully bonded to the CLTPLUS ceiling elements in the factory.

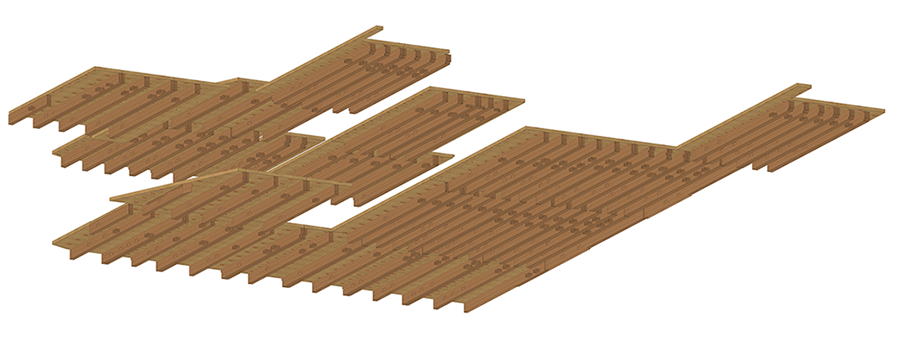

Large span thanks to ribbed ceilings

When planning spans of more than six metres, ribbed ceilings are a sensible and economical solution. Attributes such as excellent strength, enormous stability and high load-bearing capacity combined with low weight make the use of this type of ceiling so attractive. Further advantages lie in the individual design options, maximum structural performance and particularly low material consumption. In concrete terms, glued laminated timber and cross-laminated timer are connected to each other using screw press bonding. The reference Kellerberg Terrassen in Bad Aibling shows us how this looks in reality.

Large support grid and felxible ceilings with TS3

Entirely in keeping with futuristic timber construction, our key TS3 connection technology permits skeleton structures without support beams, whose aesthetic is marked by slim, point-supported panels of arbitrary size, thanks to front-side joint filling. Generous support grids and flexible ceilings can be created without pressure and without additional fasteners. The TS3 technology is used in the example of the two apartment buildings in Zollikerberg, Switzerland.

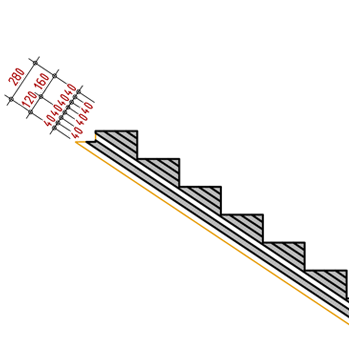

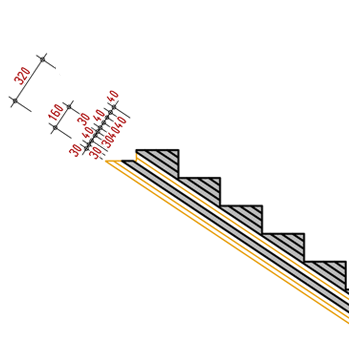

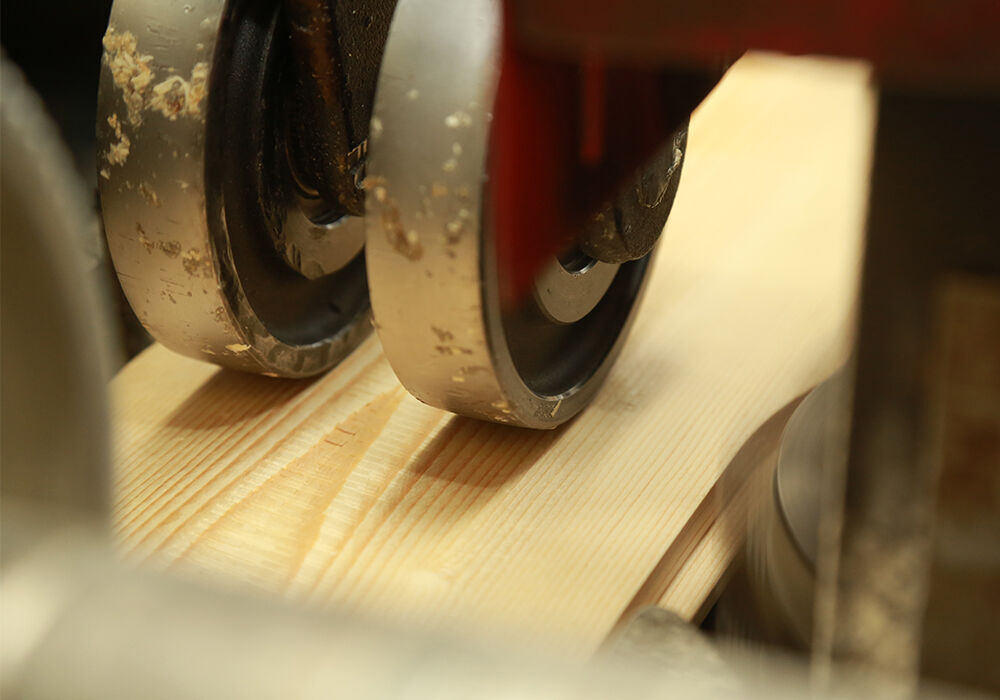

Staircase: Timber, up and down

CLTPLUS makes a convincing argument, especially in the construction of single flights of stairs: It is possible to directly connect two floors as a solid timber element without the need for an intermediate platform. The stairs are manufactured individually, tailored to the project, in the Joinery Service Centre according to the customer's specifications, and steps or lifting systems can also be produced according to structural and static requirements. The result is a ready-to-install staircase that also features impressive aesthetics, as well as design, thanks to the option of Visible Quality for the underside of the staircase.

04

ORDERING

In orders, production capacities are reserved

based on the existing planning status and the

exact delivery date is set. Our digital customer

portal is available for you to track the project

status at any time. Our TIM application also

enables secure and uniform data exchange

for plans and all documents.

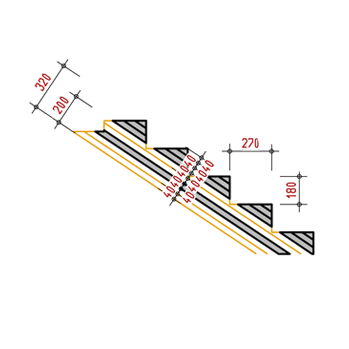

- 320 mm, to 5 m

- Construction: CLTPLUS 320 L9 for staircase construction

- L30*2-C40-L30*2-C40-C40-C40-C40

- 160 mm static support cross-section as per ETA 20/0843

- 160 mm doubling up for step formation C-transverse layers

- Underside in Industry Plus and Visible Quality upon request

- Minimum order quantity: 2.25 x 8 m

How can fine tuning between the customer, timber construction technology, production and logistics be optimised? Where can we find unused potential in data exchange and the planning process? And how can you actually determine which solid timber elements are needed and when? The future belongs to timber construction, but the innovative digital solutions from THEURL already offer the answer to all these pressing questions.

FOUR CAD PROGRAMMES

THEURL is the only industrial partner that can create joinery

plans for CLTPLUS and glued laminated timber in all

four common CAD programmes such as SEMA, Dietrich's,

cadwork and hsbcad. Whether it's a private family home or

a major project – projects of all categories are processed on

a digital twin, which contains detailed information on each

individual component.

TIM – THEURL INFORMATION MANAGER

TIM allows customers to not only keep an eye on their project

status at all times, the application also enables secure and

uniform data exchange of all plans and documents. Extensive

and large amounts of data from a wide variety of sources can

therefore be exchanged. As the interface between THEURL

and its customers, TIM provides the perfect service platform.

DISCOVER HUGE ADVANTAGES AND SAVE TIME WITH TIM.

REGISTER NOW!

PERFECT PLANNING FOR LOGISTICS

Precisely planned loading of every individual element is essential

for all construction site deliveries. This is the only way to

adhere meticulously to tight construction schedules. Specially

developed loading space optimisation allows the individual

components to be loaded onto the truck in the correct order.

This saves a lot of time on-site.