Primary school on the church square – Kirchplatz – in Wattens

Innovative solutions for modern educational institutions

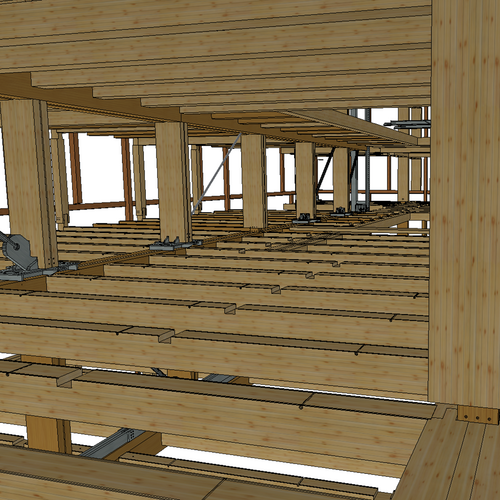

The new Wattens primary school is being created with innovative ribbed slabs, a combination of our solid wood products CLTPLUS and glued laminated timber – a modern and climate-friendly learning paradise. The sustainable materials blend harmoniously into the development on the church square and will create an inspiring environment for over 200 pupils from the autumn of 2025.

The school was designed by Studio Lois Architektur and ir architect Iris Reiter in collaboration – the winners of the general planning competition 2023. As a hybrid structure, it unites concrete construction in the basement and solid wood construction in the upper floors. THEURL has been delivering the first solid wood products to Zimmermann & Co Gmbh in Wattens since the beginning of February. The wooden construction will begin at the beginning of March and the entire wooden structure will already be complete at the end of March.

Solidity and stability with ribbed slabs of CLTPLUS and glued laminated timber

One special feature of this wooden building is the over 150 factor-finished prefab ribbed slabs of CLTPLUS ceiling components and glued laminated timber. These combine outstanding rigidity, enormous stability and high load-bearing capacity at a low weight. These have been produced since 2024 at THEURL as a special solution by trained employees in the beam processing centre, as well as through an annual in-house production inspection.

A total of 405 m³ GLT in visual quality are used, of which 236 m³ for the GLT ribbed slabs and about 170 m³ for joists and columns. In addition, over 400 m³ of CLTPLUS slab elements with strengths of 120 and 160 mm are used. The finished ribbed slabs are also equipped with a weather-resistant film over the entire CLTPLUS surface. The company's own swap bodies are used for delivery to ensure seamless and rapid construction progress.

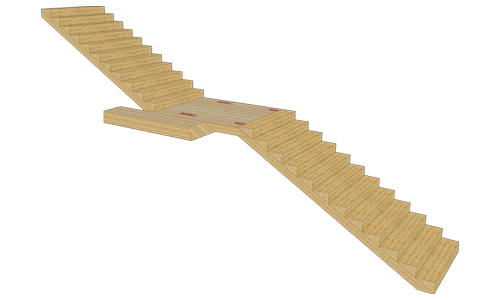

How do you make a ribbed slab element?

A ribbed slab element measures over 20 m² and is made up of two glued laminated timber ribs and a CLTPLUS slab element. In the cutting service centre, precise processing is done initially on both solid wood products. Then the glued laminated timber ribs and the CLTPLUS slab elements are connected to each other using screw-press gluing. A joint-filling dual component adhesive is used, which creates a permanent and stable bond.