The “Am Hirschen Grün” Project

An new hotel with a long-standing tradition including residential building for the centre of Salzburg

A hotel with a history that goes back to the 16th century and family who acquired the “Zum Hirschen” inn back in 1830. Just a few minutes' walk from Salzburg Central Station, it was renovated, completely refurbished and rebuilt in 2023 with modern architectural features.

Under the project name “Am Hirschengrün” Dietrich | Untertrifaller together with LP Architektur, also designed a residential building with 42 apartments and an underground car park in addition to fully renovating the hotel with its 120 rooms/suites, spa and fitness room. The historical structure was gutted, completely renovated and expanded to include an extension. The old hotel’s original mansard roof was reinstalled and the wooden ceilings were replaced and reinforced. Despite this, the existing buildings were handled carefully so that the originality of their historical rooms were preserved. A transparent bridge on the 3rd floor connects the existing building with the new building. An old stable building in the inner courtyard was renovated extensively and converted into six maisonette garden studios. The inner courtyard with flower garden, kitchen garden, play area and open spaces offers hotel guests and residents a green oasis of rest and relaxation.

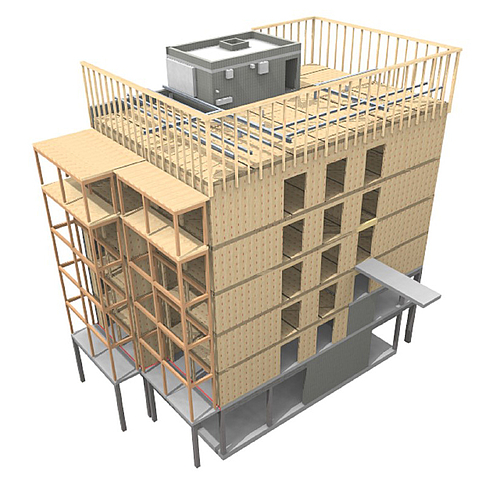

In the spirit of sustainability, the new hotel area and residential building were built using a hybrid wood construction. The concept here is wood that you can see and feel. To achieve this, 1,038 CLTPLUS components were installed, with the ceiling elements in Residential Quality remaining visible to hotel guests and residents.

Structural fire protection

All extensions and new parts are built using a hybrid construction method, with the main supporting structure being made of wood. The ground floor and staircase, as well as the fire walls to the adjoining building, are made of reinforced concrete. All load-bearing steel parts feature a fire protection coating or fire protection planking. The required level of fire protection of the load-bearing wooden components was ensured by their fire-safety design and residual cross-sectional area. The sufficient load-bearing capacity for exceptional design scenarios (reduced loads without safety features) after 90 minutes was defined using burn-off design. For example, the following applies to the walls on the lowest floor of the multistorey residential building:

- The central wall within an apartment (CLTPLUS180-7s) is protected on one side in a two-sided fire attack, while remaining visible on other side. The burn depth on the visible side is approx. 7 cm, resulting in a residual cross section of approx. 11 cm.

- The partition walls in the apartments (CLTPLUS140-5s) demonstrate a burn depth of approx. 7 cm on the visible side during a one-sided fire attack, which results in a residual cross section of approx. 7 cm.

Project progress at a glance

From planning to construction-site delivery

1. Joinery planning

Based on the submitted timber construction plan, our technical timber construction team developed a waste-optimised detailed plan for the three phases of construction, featuring all joinery details and lifting equipment, and determined the final nesting. The exchange of data for the entire project phase was processed through our B2B portal – TIM.

2. Logistics planning

The panels, which were up to 16 metres long, created logistical challenges and each delivery had to be planned precisely in advance. Using loading space optimisation (LRO), it was possible to virtually determine the correct order of the individual components in advance.

3. Production and beam cutting

Based on the approved production and cutting plans, the components were manufactured using the latest production technology and subsequently processed in the joinery service centre with high dimensional accuracy and precise execution.

4. Delivery

For smooth and just-in-time delivery to the construction site, a detailed logistics concept was created in close cooperation with our client Zimmerei Rupert Burgschwaiger. More than 23 truckloads were planned and had to be delivered from mid-June 2023 within a specified time window, while taking all the challenges of the city centre into account. In addition to many other advantages, building with wood meant that only a quarter of the trucks were needed compared to alternative construction methods.

The “Hirschengrün” project makes a significant contribution to development in the Elisabethvorstadt district of Salzburg through preservation and remodelling of its historic traditional hotel, urban densification in the city centre and contemporary timber construction methods.

Doreen Rehmer-Jeitler Arch. Dipl. Ing. (FH)

Project Manager Dietrich | Untertrifaller Architekten ZT GmbH